Innovation & Sustainability

At J de Jonge, innovation and sustainability is anchored in our mission, guiding our company toward a more responsible future. We are committed to creating a next-gen industry, characterized by autonomous operations and sustainable energy. By embracing the latest technologies and promoting a culture of safety, quality and sustainability, we aim to redefine industry standards while protecting our planet.

Our Patented Innovations

Innovation is at the heart of everything we do. By adopting innovative technologies, we boost efficiency in our operations to new heights. Examples of our innovation are:

JLA’s Liquid Hydrogen Loading Arm

Patent number: pending..

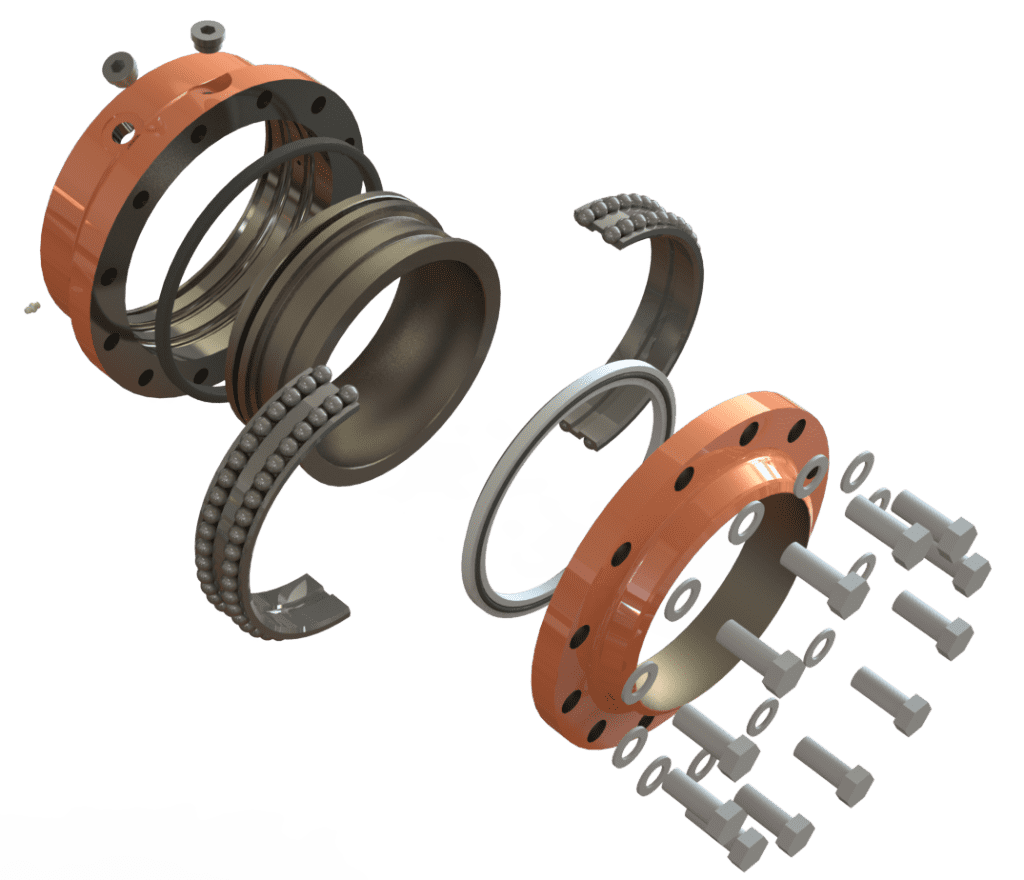

The Zero-Emission Swivel Joint

Patent number: EP3177861

TankX’s Tank Jacking System

Patent number: P35177

Smart Control for Loading Systems.

Patent number: EP2671839

Transforming Processes with Digital Innovations

At J de Jonge, we’ve gone digital to improve our operations and use less paper. We have a cloudbased platform for managing manufacturing databooks and production reports, making information easy to access and organized. Our safety and quality assurance processes are managed in the cloud, allowing for efficient oversight. Our JLS service technicians use the Smartflow app on their tablets to streamline their work and respond quickly to client needs. These digital solutions help us work more efficiently and effectively.

Our Innovation DNA

At J de Jonge, we are dedicated to creating a positive impact on the environment and society. Through our innovation values, we contribute to creating a more sustainable future.

Innovation

Innovation is at the heart of everything we do. We use the latest technologies to improve operational efficiency and advance sustainability initiatives, both within our company and through strategic partnerships. A key example of our innovation is JLA’s Liquid Hydrogen Loading Arm (LH₂), which combines full-electric actuation, advanced vacuum insulation, and integrated digital monitoring to deliver unmatched safety, efficiency, and reliability for large-scale liquid hydrogen transfer in port environments. Other examples include the zero-emission swivel joint, our tank jacking system, and JE&A’s smart control for electrified loading systems. By stimulating innovation both inside and outside of our company, we play our part in realizing a future with sustainable technology.

Transparency

Transparency is a core value in our sustainability reporting. Every quartile, we evaluate our environmental performance, covering emissions, energy reduction, and resource efficiency, and share our findings with stakeholders. We comply with EU regulations, including CSRD and CBAM, and report our sustainability performance through EcoVadis, a global sustainability platform. Additionally, every three years, we review and adjust our sustainability policies as needed. We are currently in the process of acquiring ISO 14001 certification, with external audits conducted by DNV. The latest gap analysis by DNV in Q4 2025 showed zero non-conformities. By committing to regular updates, we ensure our practices remain accountable and meet the highest environmental standards.

Collaboration

At J De Jonge, we understand that collaboration is key to achieving our sustainability goals. As members of Stichting Positieve Impact, we partner with over 280 companies to cut CO2 emissions across various sectors. Additionally, we work with GAIA Circular to recycle used Personal Protective Equipment (PPE) into new products. This reduces waste while creating jobs for those with limited market access.

We also collaborate with clients to reduce emissions. With one global client, we’re building a CO2 inventory and reduction plan addressing scope 1, scope 2, and scope 3 emissions. We even developed a specialized tool that calculates scope 3 emissions for projects, helping clients meet their sustainability goals. This tool is available for anyone who needs assistance with CO2 emissions calculations, regardless of whether you choose J de Jonge to handle your project.

In addition, we are collaborating with our client on the LH₂ MLA R&D project, which is supported by the government. The project aims to develop and fully test the Liquid Hydrogen Loading Arm (LH₂ MLA) by 2028. This collaboration highlights our innovation efforts, strengthens our industry partnerships, and underlines our contribution to the global energy transition.

Our Commitment to Sustainability

We take our commitment to sustainability seriously, embedding it in our corporate philosophy and operational practices. Our goals focus on minimizing our environmental footprint while enhancing our positive contributions to society. Here are some of our sustainability targets:

Waste Management

Increased our recycling rate to 80% by 2027.

Reduce general waste generation by 25% in 2027 compared to 2023.

Sustainable Project Solutions

We provide carbon emissions calculations and mitigation proposals on projects to our clients in 2024 via our carbon emission reduction program.

Environmental & Sustainability Certifications

Showcase our commitment to sustainability by achieving ISO 14001 certification by 2026 and obtaining a Bronze Medal in EcoVadis.

Energy & Emission Reductions

We want to reduce emission to 27% in 2027 and the energy consumption by 7% in 2027.

Our Achievements

Carbon Calculactions

We implemented carbon emissions calculations for projects, enabling us to provide clients with sustainable options.

Reduced Emissions

In 2024, we reduced Scope 1, Scope 2, and business travel emissions by 29% compared to 2022. We are also certified as a CO₂ Performance Ladder Level 3 organization.

Waste Recycling

In 2024, we successfully recycled 66% of our waste. This was achieved through improved waste separation and new modular bins.

Water Consumption

We reduced domestic water consumption by 12% in 2024, improving overall resource efficiency.

Renewable Energy Use

In 2024, we used 5% more renewable energy, including HVO and green electricity, to power our operational vehicles and facilities.

Badge of Commitment

We received the EcoVadis Committed Badge in 2024, recognizing our focus on sustainable business practices.

CO2 Performance Ladder

The CO2 Performance Ladder, managed by SKAO, helps businesses and government entities reduce carbon emissions and costs by promoting energy conservation, material optimization, and the use of sustainable energy. J de Jonge Group is certified at Level 3, reflecting our commitment to reducing our carbon footprint. We are actively implementing measures to decrease our CO2 emissions, extending our efforts beyond our offices to encompass projects. For more information about the CO2 performance ladder visit the website of the SKAO.

Sustainability at Koggehaven

Downloadable materials

Want to Learn More?

Get in touch with our colleagues and discover how we implement innovation and sustainability in our business practices. We’ll be glad to answer any questions you have!