The client operates within the international chemical industry and focuses on the production of high-purity and specialty products. Their processes demand reliable, corrosion-resistant equipment capable of withstanding demanding operating conditions and aggressive media.

J. de Jonge was awarded the fabrication of a new replacement heat exchanger built entirely from high-grade, corrosion-resistant materials.

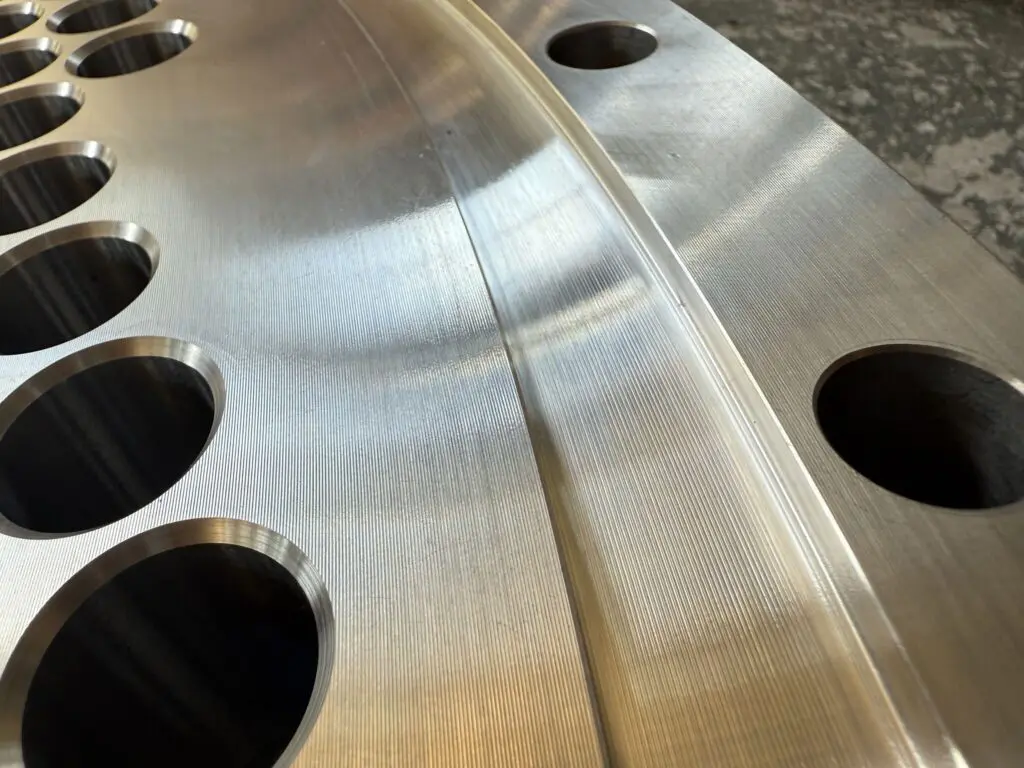

The challenge lay in the complex material combination — CuNi 70/30, Monel, Alloy 400, and Hastelloy C4 — each requiring specific welding techniques and handling procedures to ensure mechanical integrity and long-term performance.

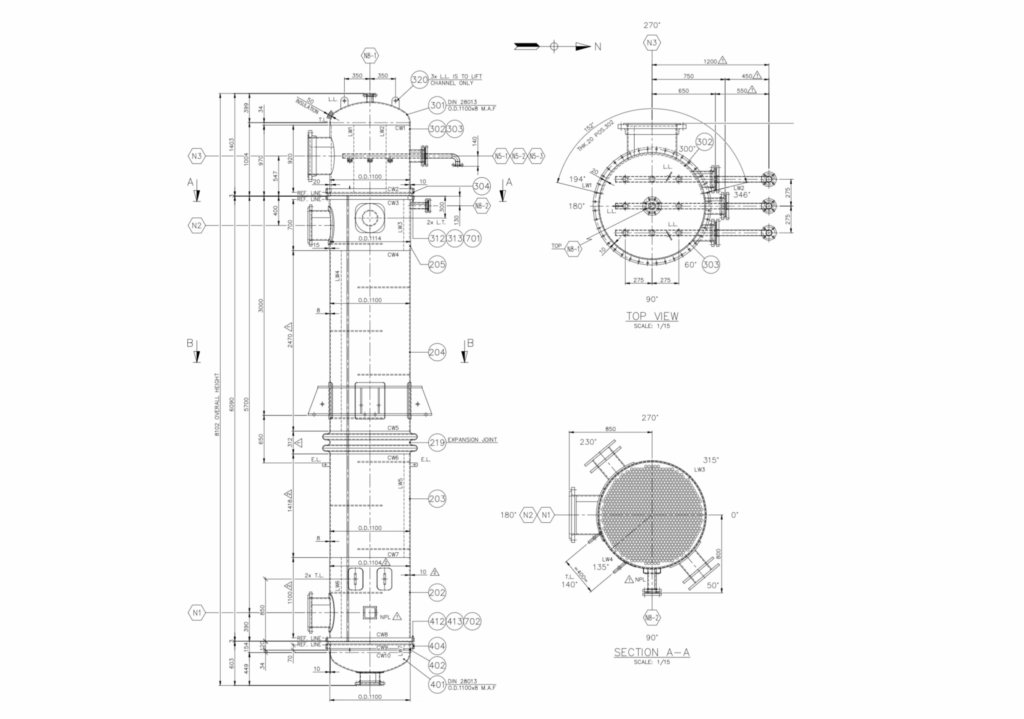

The project covers the complete fabrication of a shell-and-tube heat exchanger consisting of 947 tubes in Alloy 400 (B165 N04400), each measuring Ø25.4 × 2.11 mm and 6100 mm in length. The tubesheets and heads are made from Monel, while the shell is constructed from CuNi 70/30 and fitted with Hastelloy C4 spray nozzles for optimal corrosion resistance.

To execute the project successfully, new welding procedures were developed and qualified, expanding our welding scope to include a wider range of exotic materials. All bulk materials have been inspected and approved at the supplier’s site, and fabrication is now ready to commence in the Netherlands.

Upon completion, the new exchanger will provide the client with a durable, high-performance unit capable of operating under severe process conditions. The project further enhances J. de Jonge’s expertise in high-alloy fabrication and demonstrates our ability to deliver tailor-made solutions for complex industrial applications.

Kon. Wilhelminahaven Z.Z. 18

3134 KG Vlaardingen

The Netherlands