In this highly technical and complex project, the client based in Europoort required the engineering, manufacturing, and delivery of four advanced heat exchanger U-bundles. Two of these bundles were made from super duplex material, while the other two were made from hyper duplex material. Each bundle weighed approximately 16,500 kilograms and contained around 6,500 meters of tubing. The scope of work spanned from basic engineering all the way to the final construction, involving meticulous attention to material handling, welding, and assembly.

The project presented several challenges, particularly with the use of super duplex and hyper duplex materials, which required a strictly controlled environment to maintain their integrity. Handling seamless tubes with a wall thickness of 19.05 x 1.65 mm over a total length of 65.2 kilometers across all bundles posed significant manufacturing complexity.

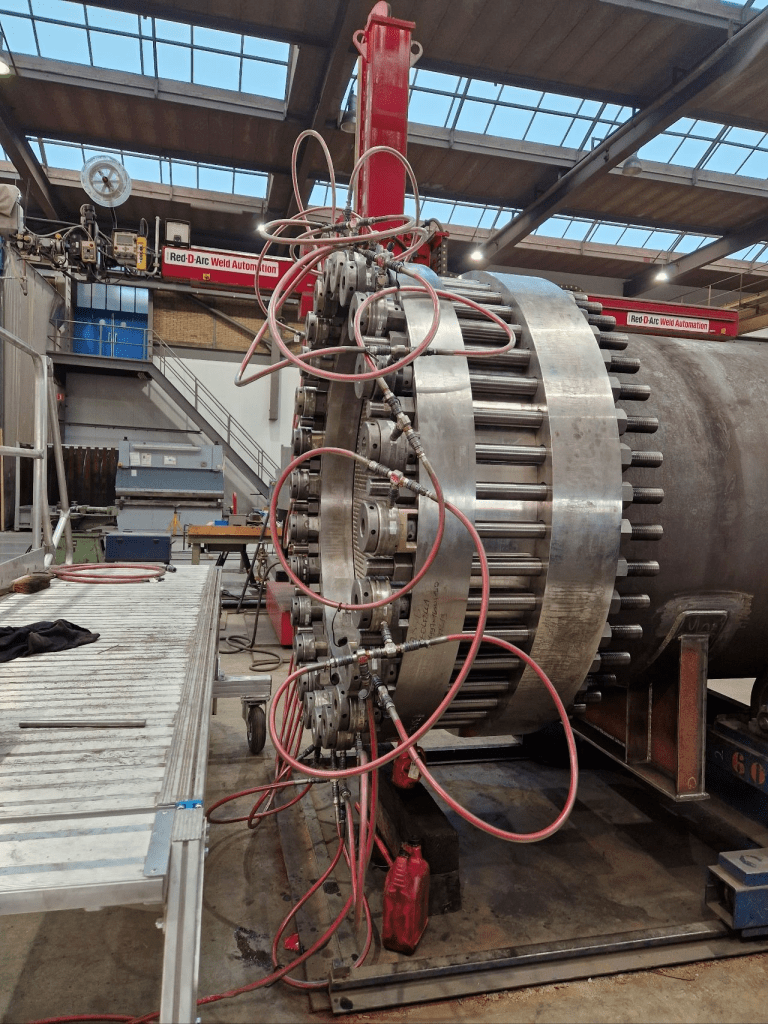

Additionally, each of the four bundles featured a tubesheet weighing over five tons, drilled with 2,500 precision-aligned holes, requiring expert welding and tube expansion techniques. The sheer volume of orbital welds—around 20,000—added to the difficulty, demanding precision and expert craftsmanship.

Logistical challenges also arose, as the bundles had to be carefully transported to prevent any contamination or damage.

The project covered every stage from basic engineering to final delivery. It began with detailed design and planning, including high-specification forging and machining techniques to meet the stringent tolerances required for the duplex materials.

Special considerations were made for material handling, necessitating the establishment of an enclosed workspace to control environmental factors such as humidity and contamination. Once the bundles were constructed, extensive quality checks were performed. The heat exchanger U-bundles were then securely packaged and delivered, ready for installation and operation.

The project was completed on schedule in January 2023, meeting all client specifications and expectations. The four heat exchanger U-bundles were successfully delivered, and upon installation, they demonstrated excellent reliability and efficiency under demanding operational conditions. The project underscored the company’s ability to deliver high-specification, large-scale engineering solutions, handling the technical and logistical complexities with precision and care.

Kon. Wilhelminahaven Z.Z. 18

3134 KG Vlaardingen

The Netherlands