Minimize Your Downtime With Our Reliable Maintenance

At J de Jonge, we know that reliable maintenance is crucial for optimal plant operation and uptime. Our dedicated maintenance teams are on-site to assist your operations through preventative maintenance. We also have a special maintenance team available around the clock, ensuring that your operations run efficiently. With 24/7 availability and skilled personnel, our response to emergencies are quick and minimize downtime.

The Maintenance Partner You Can Rely On

Safety & Quality

We adhere to strict safety, health, and environmental standards in all our maintenance activities. To uphold our high-quality standards, our systems track all maintenance tasks, ensuring transparency and accountability.

Around-the-clock Availability

Our maintenance teams are available 24/7, ensuring quick response times for any urgent needs.

Experienced Technicians

Our technicians undergo intense training, often starting in our own workshops to ensure they are equipped with the necessary skills and certifications to work in the field.

End-to-end Services with Minimal Downtime

From engineering to construction, our divisions can manage all important aspects of your maintenance. This in combination with our proactive maintenance approach reduces unplanned downtime and maximizes operational time.

We’re Here For You: Anytime, Anywhere

Our skilled on-site team is dedicated to providing consistent, high-quality maintenance services with the goal of increasing uptime and reliability. With 24/7 availability, we can work around the clock and assure you that all tasks are completed on time, no matter the situation. This commitment allows us to keep your operations running smoothly, minimizing any potential disruptions.

Top Team with Top Tools

Our maintenance teams consist of highly trained experts from every department involved in the process, from engineering to construction. The construction crew hold all necessary certifications, so they can perform the work required with confidence and competence. Next to our highly trained and qualified teams, we also own our own equipment necessary to execute maintenance projects.

- CNC Plasma cutting machine

- Bandsawing machine

- Spot welding machine

- Pipe & profile bending machines

- Press brakes

Minimal Downtime

We use prefabrication for piping systems, skids, and manifolds, all made to meet PED standards for pressure equipment. Preparing these parts ahead of time speeds up the installation process. This means we can work more efficiently and reduce down-time during on-site maintenance.

Prioritizing Safety and Quality in Every Operation

Safety is our foremost priority. Our focus on safety, health, and environmental compliance is integrated into every aspect of our work, ensuring that all operations meet requirements. We implement a safety-first approach in all maintenance activities, creating a safe work environment on-site.

To ensure quality, we conduct thorough quality and readiness checks at every stage of the project. You can be sure the end result will comply with both our high standards and industry regulations.

Do you need advice from a specialist?

Contact Edwin to know more about Mechanical

Our Projects

Our portfolio includes several maintenance projects and sites that highlight our expertise and commitment to quality. These projects and sites show we have the ability to handle complex maintenance challenges while ensuring client satisfaction

Our Activities

J de Jonge Mechanical offers a wide range of piping and mechanical

services to meet every industry requirement

Engineering

Expertise in mechanical and piping engineering, from basic to detailed engineering plan and eventually, execution.

Construction

We are specialized in delivering projects of all sizes, from large-scale EPC ventures to smaller modifications, whether in brownfield or greenfield environments.

Maintenance

Our dedicated on-site team ensures operational efficiency through routine checks and preventative maintenance, while our 24/7 service is always ready to handle urgent repairs whenever you need us.

Turnarounds

With extensive preparations and dedicated teams of up to 150 skilled men, we provide reliable execution of turnarounds with minimal downtime.

Offshore

Delivering piping and mechanical services and turnaround in offshore environments on the North Sea, including modifications and installations on platforms.

Progresso

Progresso Mechanical provides top-tier mechanical services with precision, safety, and innovation. From advanced bolting services to valve overhauls and non-destructive testing

Want to Learn More?

Get in touch with Bart & Max today to discuss your project requirements. Our team is here to help you find the best solutions for maximizing your mechanical operation.

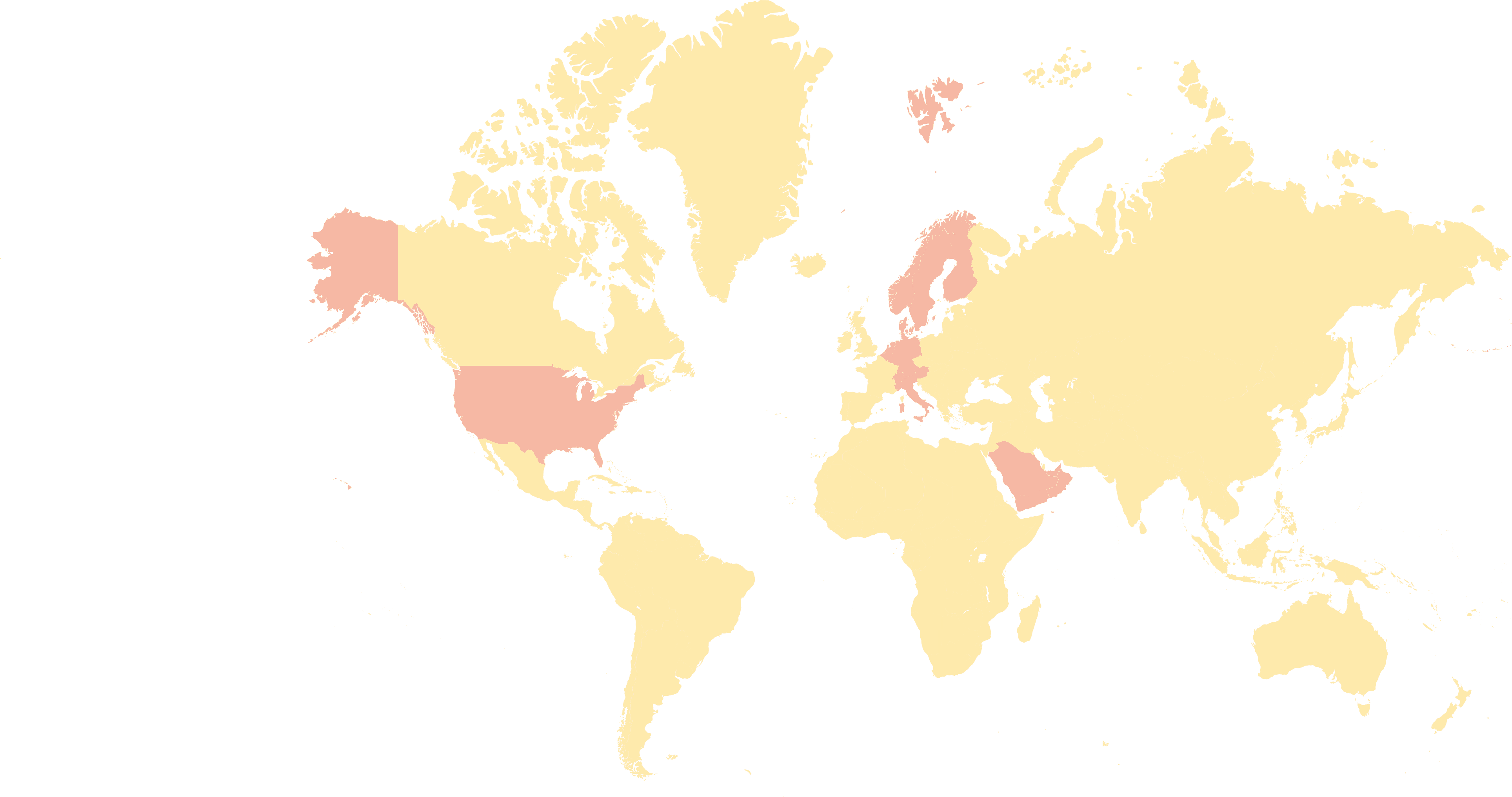

Your International Partner

- Our Projects Market

- Our Export Market