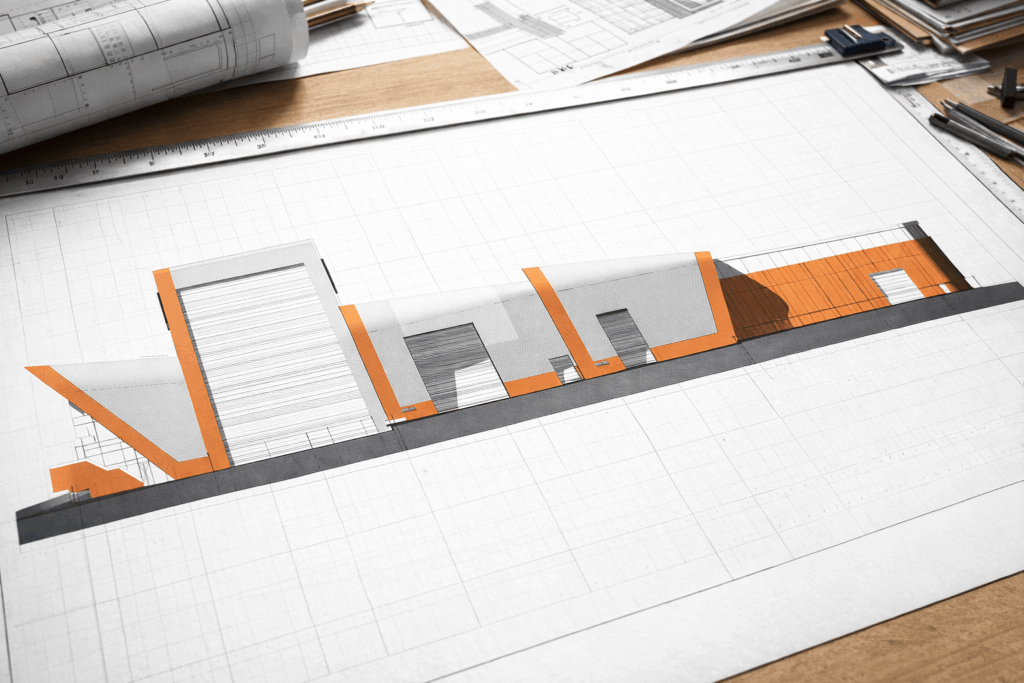

Our Fabrication Yard Vlaardingen is open!

Offshore Fabrication Yard Vlaardingen

With a total area of 30.000m2 and a load-out capacity of over 4.000 Tons our Vlaardingen Yard located on the Nieuwe Maas, offers unobstructed access to open water and a highly efficient setup for offshore fabrication projects. From conditioned prefabrication to load-out, everything is designed to keep projects moving.

Our Office with external workspace

for up to 40 personnel

RoRo and barge-based delivery,

supported by SPMT transport.

Direct Access to Open Water

Direct and unobstructed access to open water, enabling efficient load-outs and a sailing time of 20 minutes to sea.

Strategic

Location

Situated on the Nieuwe Maas near Rotterdam, with an on-site quay and direct connections to suppliers, ports and offshore routes.

Focus on Small Platforms

Optimised for small to mid-size offshore platforms and modules, ensuring flexibility, short lines and full project attention.

International Accessibility

Rotterdam Airport – 15 min

Schiphol Airport – 40 min

Brussel Airport – 1 h 55 min

Antwerpen Harbour – 60 min

Metro Station – 5 min walk

Our Office

Hall 1

Dimensions: 100 × 30 × 22/42 m

Crane Capacity: 2×100t, 2×40t

Hall 2

Dimensions: 100 × 23 × 22 m

Crane Capacity: 1×40t, 1×20t, 1x10t

Hall 3

Dimensions: 100 × 30 × 22 m

Crane Capacity: 2×20t, 1×10t

Fabrication Shop

Dimensions: 45 × 80 × 17 m

Crane Capacity: 1×30t, 1×20t, 1×15t, 2×6.3t, 1×5t, 2×3.2t

Facilities & Capacity

Our fabrication yard is equipped to support efficient, safe and high-quality construction across all project phases.

Type of Work

- Offshore Modules

- Brownfield Modifications

- Skids, Frames, Pipe racks

- Offshore Prefabrication

- Marine Loading Arms

- Hose Towers

- New Pumps

- Heat Exchangers

- Loading Arm Repair

- Pump Repair

Sectors we Support

- Wind Energy

- Oil & Gas

- Hydrogen & Energy transition

- CCUS

Conditioned & Coated Halls

Suitable for year-round fabrication and assembly under controlled conditions.

Quay & Load-out Facilities

Suitable for heavy load-outs

and offshore transport.

Outdoor Lifting & Storage

Suitable for heavy lifts, outdoor assembly

and flexible storage.

All Technical Specifications

Location & Facility

Prefabrication Shop

Assembly Hall 1

Assembly Hall 2

Assembly Hall 3

First Floor

Blasting & Painting Shop 1

Blasting & Painting Shop 2

Open Assembly Area

Tower Crane

Warehouses

Open Storage

Load-out Quay

Load-out Capacity

Jetty

Harbour Quay

Dimensions (L × W × H)

45 × 80 × 17 m

100 × 30 × 22/42 m

100 × 23 × 22 m

100 × 30 × 22 m

Height: 6.7 m, Area: 1.800 m²

30 × 5 × 6.5 m

30 × 5 × 6.5 m

>15.000 m²

Height: 60 m, Length: 70 m

1.200 m² (climate-controlled)

7.000 m²

50 m Wide, 140 m Long

>4.000t

Length: 140 m, Water depth: 5.5 m

150 m with on-site berthing facilities

Crane Configuration & Capacity

1×30t, 1×20t, 1×15t, 2×6.3t, 1×5t, 2×3.2t

2×100t, 2×40t

1×40t, 1×20t, 1×10t

2×20t, 1×10t

–

–

–

–

40t up to 23 m, 11.3t up to 72 m

–

–

–

–

–

–

Experience & Expertise

Backed by more than 70 years of offshore experience within the J. de Jonge Group, the Vlaardingen Fabrication Yard has a proven track record in oil and gas, offshore wind and energy transition projects. Projects are executed by multidisciplinary teams of certified specialists, supported by experienced project managers who understand offshore requirements and constraints. From early project involvement to final load-out, expertise is available in-house to ensure safe execution, realistic planning and reliable delivery.

Safety & Quality

Safety and quality are integral to all yard activities and executed in line with internationally recognised standards, including ISO 9001, ISO 14001 and ISO 45001. Welding is performed in accordance with NEN-EN 3834 requirements.

Quality is safeguarded through strict QA/QC procedures, including 100% NDT on critical welds. Blasting and painting are carried out in-house, ensuring full control over coating quality and planning.

Integrated & Future-Ready Fabrication

Our fabrication approach combines integrated in-house expertise with a future-ready mindset. By bringing engineering, fabrication and project execution together at one location, we maintain full control over quality, planning and costs, while remaining flexible and responsive to project demands.

Sustainable & Innovative Execution

CO₂ reduction initiatives and the use of green power are integrated into yard operations. The yard actively supports offshore wind, hydrogen and gas projects within the energy transition.

Flexible & Fast

Project Delivery

Short decision lines and a tailored, no-bureaucracy approach enable fast turnaround times. This ensures reliable execution, even under tight project schedules.

Integrated

Full-Service Support

Engineering, fabrication, load-out and offshore hook-up are delivered within one integrated scope. In-house capabilities ensure clear planning, cost control and a single point of contact.

Ready to Discuss Your Next Fabrication Project?

Get in touch with our team to explore how the Fabrication Yard can support your scope.