The client, previously a terminal focused on the storage and blending of traditional fuels, shifted its operations towards the handling of biofuels. This transition required the development of specialized pumping systems that could accommodate the diverse and aggressive properties of biofuels while maintaining high efficiency. HLP was invited to design a tailored solution that would meet the specific demands of this new biofuel terminal.

The main challenge was designing a pump system capable of handling fluids that are both abrasive and aggressive, with a wide range of viscosities. The pump needed to be capable of fully emptying each tank, including the connected pipelines, which meant it had to operate with an extremely low NPSHr value and be resistant to dry running.

These stringent requirements presented a complex engineering task that demanded precision and reliability.

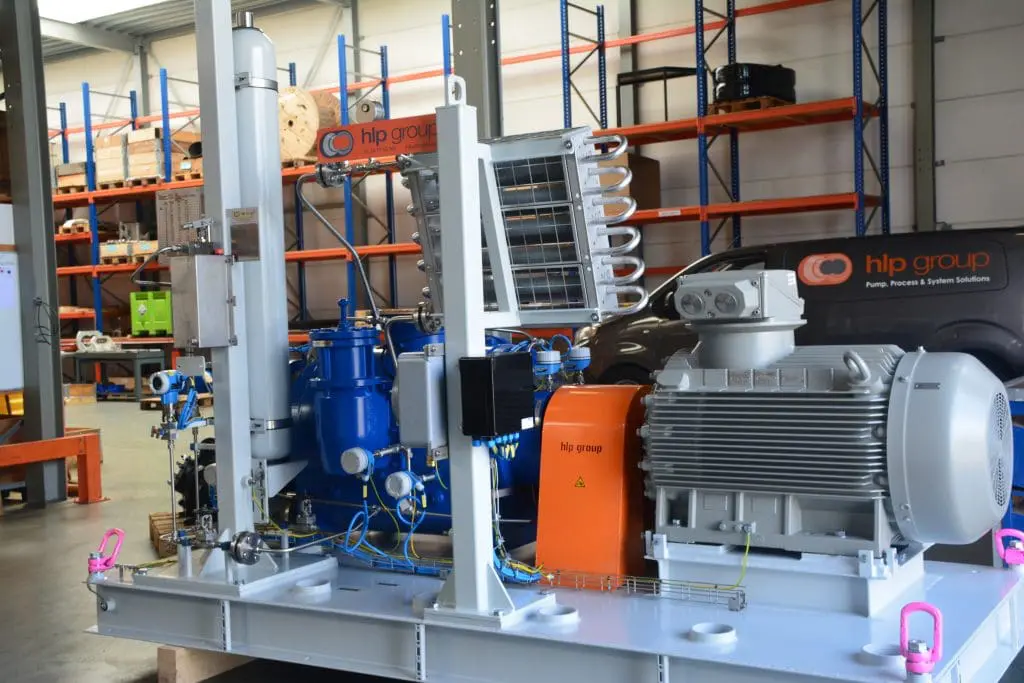

HLP engineered a custom two-screw pump system specifically designed to meet these challenges. The pump was constructed with a range of materials capable of withstanding the extreme conditions posed by biofuels.

With a low power consumption and energy efficiency of 82%, the pump operates efficiently while minimizing energy costs. A double mechanical seal, combined with a Plan 53B seal system, ensures the seals remain secure and leak-free during operation.

Additionally, the pump is equipped with a heating system to maintain both the pump and the biofuel at optimal temperatures. Smart sensors and a sophisticated SMART control system were integrated to ensure the entire process operates at peak efficiency.

The custom-designed two-screw pump met all the client’s requirements, offering an energy-efficient solution for handling biofuels with varying viscosities and aggressive characteristics. The pump system’s design, which includes advanced sealing and temperature control, ensures reliability under demanding conditions. With the integration of smart technology, the system provides real-time data, allowing for optimal operation and management of the biofuel terminal. The project successfully provided a sustainable, low-energy solution tailored to the evolving needs of the biofuel industry.