Our client is an international company in the oil and chemical industry. The subject pump, a large Begeman deepwell pump, had been in operation for several years and was nearing the end of its service life. The brand was no longer available on the market, and spare parts had become increasingly difficult to source. The client requested us to investigate the possibilities for overhauling and upgrading the pump so it could continue to be operational for several more years.

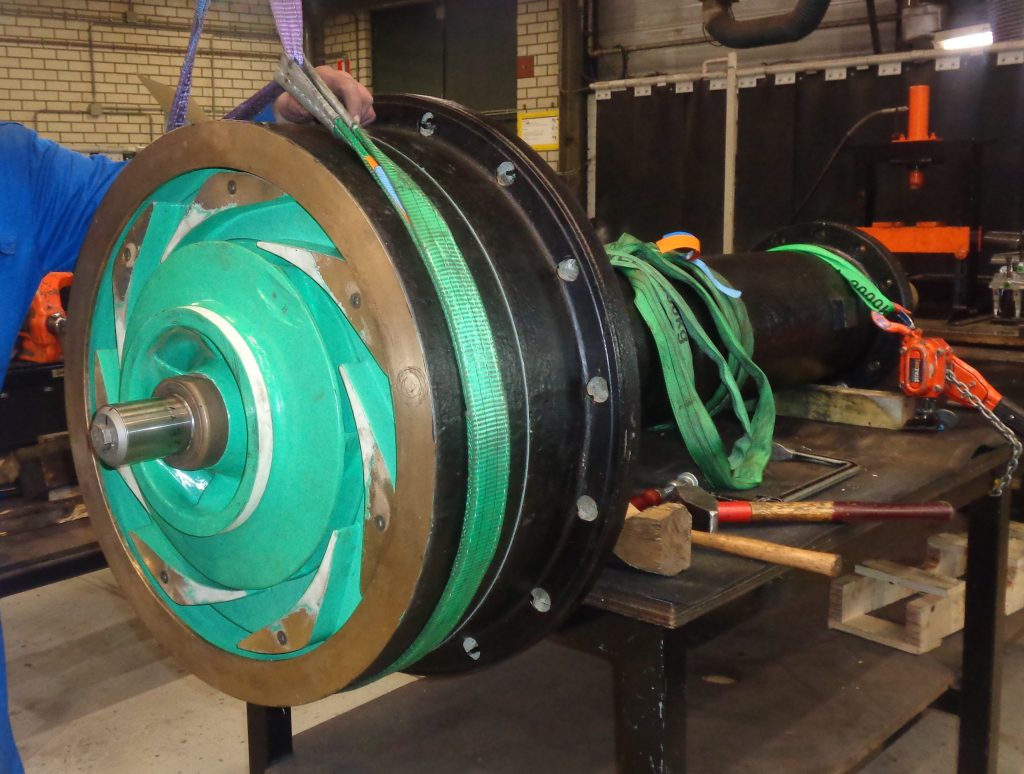

Upon receiving the pump for inspection, we discovered several critical issues. Main components such as the shafts, bearings, coupling, and bushings were worn, with some parts heavily corroded and others completely seized.

In addition to the overhaul, the client requested a modification to the sealing system, replacing the standard stuffing box sleeve with a Liquidyne seal.

The client required the pump to be returned to service within a very tight timeframe. After the pump was delivered to our Vlaardingen shop, a thorough inspection was conducted.

A detailed report, including our recommendations and the proposed modification for the sealing system, was discussed with the client. All parts were overhauled, repaired where necessary, and modified to accommodate the new sealing plan. As part of the standard process, all soft parts were replaced. Intermediate inspections were carried out to ensure that each part met quality standards before the pump was reassembled.

After final assembly, the pump underwent functional testing. The last step was applying a coating according to the client’s specifications to ensure its durability.

The deepwell pump was fully overhauled and ready for installation at the site. The work was completed on time, including the requested modification, and the client was highly satisfied with the outcome.