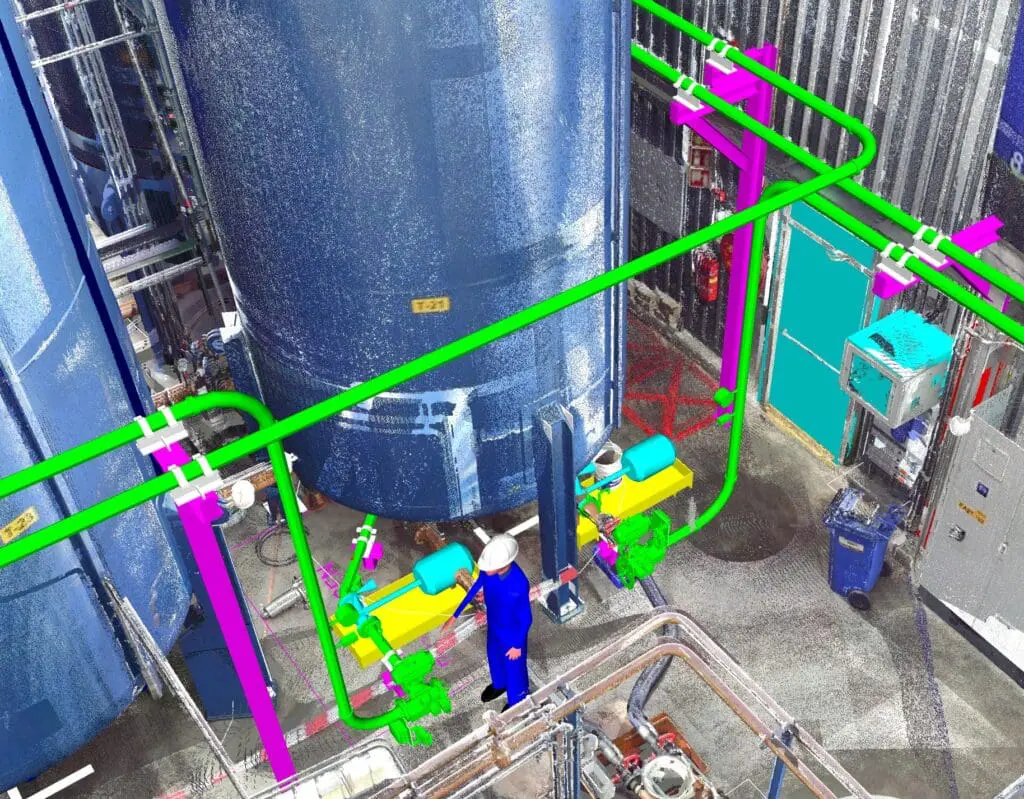

This project focused on integrating multiple product transfer lines with filling machines through custom-designed pigging systems and elevated platforms. The work involved detailed engineering, structural design, and installation across several production halls.

The main challenge was to implement the new pigging and platform systems within an active production environment. Space limitations, complex routing through existing structures, and the need to maintain production uptime required precise planning, coordination, and a highly tailored engineering approach.

The project combined detailed engineering, structural design, and installation activities to create a seamless connection between product transfer systems and production equipment.

Key highlights included:

Installation of new pigging stations at optimized layout positions for efficient routing and accessibility.

Design and integration of custom platforms connected to existing structures for safe access and equipment placement.

Engineering of piping routes over pipe racks, through walls, and into production halls.

Placement of filter units on platforms with sloped connections to filling machines.

Relocation and adaptation of existing systems to improve layout and operational efficiency.

Preparation of tie-ins for future pipeline connections from the tank farm to production areas.

Design of secondary steel structures and two elevated platforms.

Extension of compressed air lines to new platforms for operational support.

The integration delivered a clean, efficient, and future-ready transfer system. The optimized layout improved operational flow and safety while minimizing disruption to ongoing production.

Kon. Wilhelminahaven Z.Z. 18

3134 KG Vlaardingen

The Netherlands