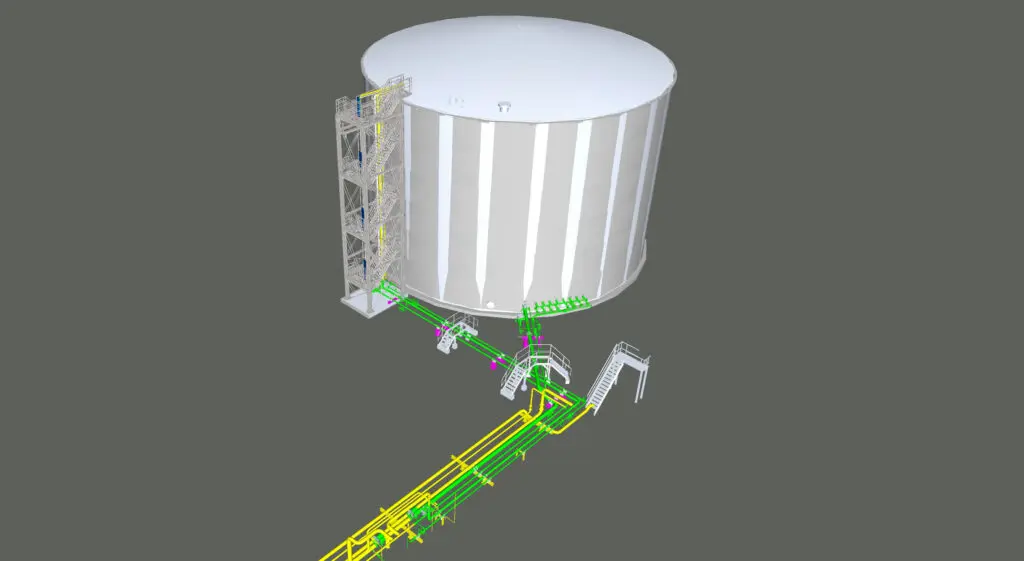

Aglobis sources, markets, and distributes sulfur and sulfuric acid across Europe. The company operates a dedicated storage tank terminal at Europoort in Rotterdam, supporting reliable logistics and bulk handling. For the safe and dependable transport of molten sulfur, jacketed piping is used — ensuring temperature control and preventing solidification during transfer.

To enhance process efficiency and thermal control within the production environment, Aglobis initiated the Jacketed Line Project. The objective was to design and install a reliable pipeline system that maintains optimal temperature conditions for molten sulfur, ensuring consistent flow and operational safety.

The project involved the design, fabrication, and installation of a jacketed pipeline system tailored to Aglobis’ operations.

Key aspects included:

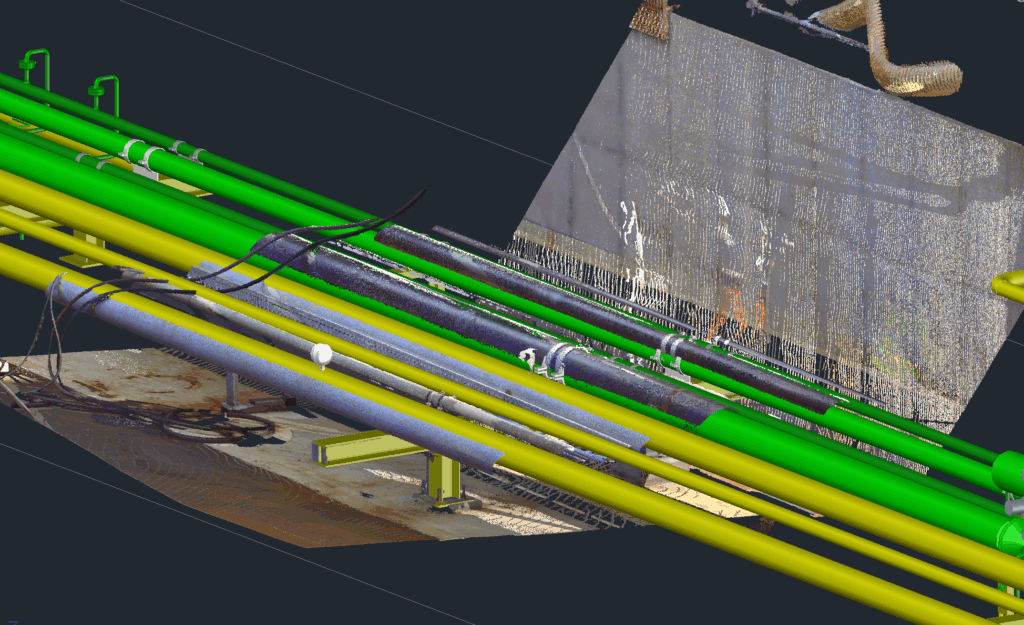

As-built 3D scanning: Using FARO 3D scanners, JMEC captured the existing site to reduce design errors and improve clash detection.

Custom engineering: Development of a jacketed line system meeting stringent operational and safety requirements.

Integration: Seamless connection with existing infrastructure while minimizing downtime during installation.

The new jacketed pipeline system successfully improved temperature stability and energy efficiency during sulfur transfer operations. By combining precise engineering with advanced 3D scanning and fabrication, the solution enhanced process reliability while minimizing maintenance and operational risks.

Kon. Wilhelminahaven Z.Z. 18

3134 KG Vlaardingen

The Netherlands